ATC Orion 8: Dielectric Sputter System: Difference between revisions

m (Removed link to Equipment Status under Resources since the status can be viewed directly by users in FBS, per Tiffany 4/15/24 sg) |

|||

| (14 intermediate revisions by 4 users not shown) | |||

| Line 13: | Line 13: | ||

|Model = ATC Orion 8 | |Model = ATC Orion 8 | ||

|Techniques = Magnetron Sputtering<br>(RF,DC, pulsed DC),<br>In-situ Plasma Etch &<br>Surface Cleaning,</br>Reactive Sputtering,<br>Co-Sputtering | |Techniques = Magnetron Sputtering<br>(RF,DC, pulsed DC),<br>In-situ Plasma Etch &<br>Surface Cleaning,</br>Reactive Sputtering,<br>Co-Sputtering | ||

|EmailList = kni-sputter | |EmailList = kni-sputter | ||

|EmailListName = Sputter | |EmailListName = Sputter | ||

}} | }} | ||

| Line 36: | Line 36: | ||

* [https://caltech.box.com/s/z3u5bywcp0vlg4usb73i46v0ggnfuooi Troubleshooting Guide] | * [https://caltech.box.com/s/z3u5bywcp0vlg4usb73i46v0ggnfuooi Troubleshooting Guide] | ||

* [https://caltech.box.com/s/6q6vh9resic35esnczpipwse1b2nlnrc Reference/supplemental Materials] | * [https://caltech.box.com/s/6q6vh9resic35esnczpipwse1b2nlnrc Reference/supplemental Materials] | ||

* [https://caltech.box.com/s/1wl0hntcbzskq05im9lxdqjl0irtkir2 Sputter gun cable swap instructions] | |||

* [https://caltech.box.com/s/sca3m472qwie0uehx6uv1strte3w2nxx QCM Deposition Rate Measurement Instructions] | |||

=== Tool Reservation Rules === | |||

{| class="wikitable" | |||

|- | |||

! !! Advanced Reservation (days) !! Limit per Reservation (hrs) !! Limit per week (hrs) | |||

|- | |||

| Weekday || 7 || 12 || 12 | |||

|- | |||

| Weeknight || 7 || 12 || 12 | |||

|- | |||

| Weekend || 7 || 24 || 24 | |||

|} | |||

===== Process Recipes ===== | |||

* [https://caltech.box.com/s/z043k1ne91oowp70lzt69kau0u2nq79f SnO<sub>2</sub> sputtering recipe] | |||

* [https://caltech.box.com/s/oxxv5sy3j7wbqyjc8r9x2wqheabne2lg NbO<sub>x</sub> sputtering recipe] | |||

* [https://caltech.box.com/s/95qrpvvggcaztmpc7whd9v9o4d9rih5x TiO<sub>2</sub> sputtering recipe] | |||

* [https://caltech.box.com/s/k669kh04xglamkidhuo7xq04xan146xt AlN sputtering recipe] | |||

* [https://caltech.box.com/s/7cqdk2g5ic2wa35lu4y2fu03esfk7sdy Al<sub>2</sub>O<sub>3</sub> sputtering recipe] | |||

* [https://caltech.box.com/s/vbjlzmbprhw1sg3auoz1oso5clwrme87 In-situ (dielectric sputter) RF plasma etch of thermal SiO2] | |||

* [https://caltech.box.com/s/a49yh35hkb2x5qnskivzde0y8z0o4cpn Guide to maintaining a plasma using gradual pressure changes] | |||

* [https://caltech.box.com/s/33nf5yz3iuebm3fkhn303rhul1hpiwie Material Deposition Overview - Indium-Tin Oxide] | |||

===== Video Tutorials ===== | ===== Video Tutorials ===== | ||

* [https://youtu.be/y7JbzNZwZvs KNI Intro to Sputtering Presentation] | * [https://youtu.be/y7JbzNZwZvs KNI Intro to Sputtering Presentation] | ||

* [https://youtu.be/MlxUnwviBiI Dielectric Sputter Training] | * [https://youtu.be/MlxUnwviBiI Dielectric Sputter Training] | ||

* [https://youtu.be/FlSFfF8C6WQ Advanced Layer Creation - Part 1] | |||

* [https://youtu.be/Ymb-mZGOjgw Advanced Layer Creation - Part 2] | |||

===== Current Target Status ===== | ===== Current Target Status ===== | ||

| Line 66: | Line 92: | ||

*** Frequency range: 1-100 kHz | *** Frequency range: 1-100 kHz | ||

*** This unit is ideal for reactively sputtering dielectrics from metal targets | *** This unit is ideal for reactively sputtering dielectrics from metal targets | ||

== Related Instrumentation in the KNI == | == Related Instrumentation in the KNI == | ||

===== Sputtering Systems ===== | ===== Sputtering Systems ===== | ||

* [[ATC Orion 8: Dielectric Sputter System|ATC Orion 8: Dielectric Sputter System]] | |||

* [[ATC Orion 8: Chalcogenide Sputter System|ATC Orion 8: Chalcogenide Sputter System]] | * [[ATC Orion 8: Chalcogenide Sputter System|ATC Orion 8: Chalcogenide Sputter System]] | ||

Latest revision as of 23:06, 15 April 2024

|

Description

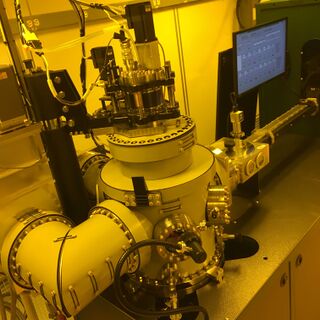

The AJA UHV Orion dielectric sputter system is capable of reaching UHV pressures as low as 1E-10 Torr. It is equipped with a load lock that allows for automatic sample transfer. There are eight magnetron guns, seven 2" guns, and one 3" gun. A total of two RF and three DC power supplies can be used on any of the eight guns, some with an internal switch box allowing for one power source to be sequentially routed to different guns, enabling automatic processes without manual cable swapping. One of the DC guns is a pulsed DC supply. Uniformity across a 6" wafer is <5% variation for the 2" guns. Pre-mixed targets of specific alloys and compounds may be sputtered. In addition, having multiple power supplies allows for co-sputtering of up to five materials simultaneously. Reactive sputtering may be performed by introducing oxygen and/or nitrogen into the chamber during process, allowing oxides and nitrides to be formed from pure metal targets. The pulsed DC supply is ideally suited for such reactive processes where a dielectric material is synthesized. Co-sputtering multiple elements in a reactive process can produce complex ceramics. An RF power supply is also present specifically for generating a localized plasma at the substrate. This can be used as a surface cleaner, etcher, for techniques such as ion-assisted deposition, and to assist in the reactive formation of metal-nitrides. This tool is also capable of substrate heating up to 800 °C, which can be used to facilitate reactions, alloying, to control film stress, and to control crystal growth mechanisms.

Reasons to Utilize Sputtering

- Ability to synthesize compounds and control compositions

- Wide variety of high quality oxides & nitrides may be synthesized

- Generally produces more uniform, better adhering films when compared to evaporation

- More conformal sidewall coverage for coating patterned substrates

- More conformal than evaporation, less conformal than CVD & ALD

Applications

- Metal and dielectric deposition

- Surface cleaning & in-situ plasma etch

- Ion-Assisted Deposition

Resources

SOPs & Troubleshooting

- KNI SOP

- Troubleshooting Guide

- Reference/supplemental Materials

- Sputter gun cable swap instructions

- QCM Deposition Rate Measurement Instructions

Tool Reservation Rules

| Advanced Reservation (days) | Limit per Reservation (hrs) | Limit per week (hrs) | |

|---|---|---|---|

| Weekday | 7 | 12 | 12 |

| Weeknight | 7 | 12 | 12 |

| Weekend | 7 | 24 | 24 |

Process Recipes

- SnO2 sputtering recipe

- NbOx sputtering recipe

- TiO2 sputtering recipe

- AlN sputtering recipe

- Al2O3 sputtering recipe

- In-situ (dielectric sputter) RF plasma etch of thermal SiO2

- Guide to maintaining a plasma using gradual pressure changes

- Material Deposition Overview - Indium-Tin Oxide

Video Tutorials

- KNI Intro to Sputtering Presentation

- Dielectric Sputter Training

- Advanced Layer Creation - Part 1

- Advanced Layer Creation - Part 2

Current Target Status

The following link will take you to a document which displays the current target configuration. This is updated after each time targets are rearranged.

Specifications

Hardware Specifications

- Typical base pressure: 1E-9 to 1E-10 Torr

- All dry pumping system (cryo & turbo & roots & diaphragm pumps)

- Load-lock-equipped system with automatic sample transfer

- Substrate holder accepts 150 mm and 100 mm wafers, as well as small chips affixed via pressure clips

- Substrate heating up to 800 °C provided by backside heating lamps

- Semiconductor grade Ar, N2, O2 process gases

- Eight Magnetron sputter guns

- Seven confocally-oriented 2" guns (faces substrate at angle)

- One centrally-located 3" gun (directly faces substrate)

- Power Supplies:

- Three RF Supplies

- One 100 W supply for substrate plasma generation

- One 600 W

- One 300 W, equipped with 3-position switch router which enables sequential switching between 3 connected magnetrons

- Two 1500 W DC

- One 2000 W pulsed DC

- Equipped with a two-position switch router that enables sequential switching between two connected magnetrons

- Frequency range: 1-100 kHz

- This unit is ideal for reactively sputtering dielectrics from metal targets

- Three RF Supplies