Nova 200 NanoLab: SEM & EDS: Difference between revisions

Jump to navigation

Jump to search

m (→Specifications) |

No edit summary |

||

| Line 25: | Line 25: | ||

* Tungsten deposition via Gas Injection System (GIS) | * Tungsten deposition via Gas Injection System (GIS) | ||

* Automated imaging with RunScript program & AutoScript language | * Automated imaging with RunScript program & AutoScript language | ||

===== EDS & WDS Applications ===== | ===== EDS & WDS Applications ===== | ||

* Spectrum acquisition for quantitative compositional analysis | * Spectrum acquisition for quantitative compositional analysis | ||

| Line 36: | Line 35: | ||

* EDS SOPs ([https://caltech.box.com/s/52uckmx1silq90vq918gziohjtbqzyh5 Short Version] | [https://caltech.box.com/s/kukccwu1m8ekfjo6jds4jupvzwsjs3z1 Long Version]) | * EDS SOPs ([https://caltech.box.com/s/52uckmx1silq90vq918gziohjtbqzyh5 Short Version] | [https://caltech.box.com/s/kukccwu1m8ekfjo6jds4jupvzwsjs3z1 Long Version]) | ||

* [https://caltech.box.com/s/sz9pai0icsntnef6me23veiwtwdui0gm Troubleshooting Guide] | * [https://caltech.box.com/s/sz9pai0icsntnef6me23veiwtwdui0gm Troubleshooting Guide] | ||

===== Video Tutorials ===== | ===== Video Tutorials ===== | ||

* [https://youtu.be/UfF_ljwvepQ Getting Started] | [https://youtu.be/luC-5TgNPsQ Basic SEM Alignment] | * [https://youtu.be/UfF_ljwvepQ Getting Started] | [https://youtu.be/luC-5TgNPsQ Basic SEM Alignment] | ||

| Line 46: | Line 44: | ||

* [https://caltech.box.com/s/k2iy75hxiwkehv0ogqelz2sux9e1cs5k SEM Alignments] | * [https://caltech.box.com/s/k2iy75hxiwkehv0ogqelz2sux9e1cs5k SEM Alignments] | ||

* [https://caltech.box.com/s/ijd8gprg9gcavb6of5uegu7osinzsdet Guide to Optimizing SEM Imaging] | * [https://caltech.box.com/s/ijd8gprg9gcavb6of5uegu7osinzsdet Guide to Optimizing SEM Imaging] | ||

===== Presentations ===== | ===== Presentations ===== | ||

* [https://caltech.box.com/s/lulkj0pwm053akyya1shazg8wzgudq9f Scanning Electron Microscopy: Principles, Techniques & Applications] (includes sides on EDS & WDS) | * [https://caltech.box.com/s/lulkj0pwm053akyya1shazg8wzgudq9f Scanning Electron Microscopy: Principles, Techniques & Applications] (includes sides on EDS & WDS) | ||

===== Manufacturer Manuals ===== | ===== Manufacturer Manuals ===== | ||

* [https://caltech.box.com/s/og4309108q4k2jwhkaxqtpiujg2al5iu Nova NanoLab Operation Manual] | * [https://caltech.box.com/s/og4309108q4k2jwhkaxqtpiujg2al5iu Nova NanoLab Operation Manual] | ||

| Line 59: | Line 55: | ||

* [https://caltech.box.com/s/n0abqy5z1e9a8hbyf38qybxu86sqz3vb Scripting – AutoScript Language Manual (year 2005 Technical Note: less complete, still useful)] | * [https://caltech.box.com/s/n0abqy5z1e9a8hbyf38qybxu86sqz3vb Scripting – AutoScript Language Manual (year 2005 Technical Note: less complete, still useful)] | ||

* [https://caltech.box.com/s/tlqgvtkkiahi261megm087i61gqlfzrc Scripting – RunScript Manual] | * [https://caltech.box.com/s/tlqgvtkkiahi261megm087i61gqlfzrc Scripting – RunScript Manual] | ||

===== Simulation Software ===== | ===== Simulation Software ===== | ||

* [http://www.gel.usherbrooke.ca/casino/What.html CASINO Electron Beam Simulation Software] – simulate e-beam/specimen interactions (very useful for EDS & WDS) | * [http://www.gel.usherbrooke.ca/casino/What.html CASINO Electron Beam Simulation Software] – simulate e-beam/specimen interactions (very useful for EDS & WDS) | ||

* [http://www.srim.org/ The Stopping & Range of Ions in Matter (SRIM)] – simulate i-beam/specimen interactions | * [http://www.srim.org/ The Stopping & Range of Ions in Matter (SRIM)] – simulate i-beam/specimen interactions | ||

===== Calibrate Measurements with NIST Standard ===== | |||

* The KNI has a NIST-traceable standard against which SEM measurements can be compared. See Slides 54-55 of the [https://caltech.box.com/s/lulkj0pwm053akyya1shazg8wzgudq9f SEM Presentation] for details. Ask staff for help finding and using the standard in the lab. | |||

===== Sample Preparation ===== | |||

* Use the [[Leica EM ACE600: Carbon Evaporator | Carbon Evaporator]] to make non-conductive samples conductive by applying 2-10 nm of evaporated carbon. | |||

* Use the [[Tergeo Plus ICP- & CCP-RIE: Oxygen & Argon Plasma Cleaner | | |||

O<sub>2</sub>/Ar Plasma Cleaner]] to remove hydrocarbons from the sample surface to avoid creating dark contamination spots on your features while imaging them. | |||

===== Order Your Own Stubs ===== | ===== Order Your Own Stubs ===== | ||

* Stubs used for mounting specimens are considered a personal, consumable item in the KNI. There are some old stubs at each SEM, yet you should buy your own so that you can keep them clean and available to you. There are many stub geometries and configurations, some of which will be right for you to purchase and keep with your other cleanroom items. | * Stubs used for mounting specimens are considered a personal, consumable item in the KNI. There are some old stubs at each SEM, yet you should buy your own so that you can keep them clean and available to you. There are many stub geometries and configurations, some of which will be right for you to purchase and keep with your other cleanroom items. | ||

Revision as of 20:48, 6 May 2019

|

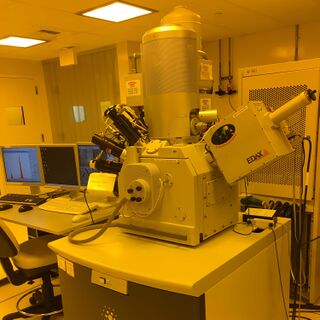

Description

The Nova 200 is the KNI's highest-resolution field-emission gun (FEG) analytical scanning electron microscope (SEM), equipped with an immersion lens for imaging sub-10 nm features and both energy dispersive spectroscopy (EDS) and wavelength dispersive spectroscopy (WDS) detectors for compositional analysis. It is also outfitted with a gallium focused ion beam (Ga-FIB) column, which is currently not operational because the Nova 600 NanoLab and ORION NanoFab together meet the KNI's Ga-FIB demand; Ga-FIB could be reactivated on the Nova 200 the future. See a full list of training and educational resources for this instrument below.

SEM Applications

- Ultra-High-Resolution Imaging (Immersion Mode aka UHR Mode)

- High-Resolution Imaging (Field-Free Mode aka Normal Mode)

- Secondary Electron (SE) imaging with an Everhart-Thornley Detector (ETD) & Through-the-Lens Detector (TLD)

- Backscattered Electron (BSE) imaging with a TLD

- Tungsten deposition via Gas Injection System (GIS)

- Automated imaging with RunScript program & AutoScript language

EDS & WDS Applications

- Spectrum acquisition for quantitative compositional analysis

- Linescan acquisition for 1D spatial compositional analysis

- Map acquisition for 2D spatial compositional analysis

Resources

SOPs & Troubleshooting

- SEM SOPs (Short Version | Long Version)

- EDS SOPs (Short Version | Long Version)

- Troubleshooting Guide

Video Tutorials

- Getting Started | Basic SEM Alignment

- Astigmatism Correction (Details | On Right-Angle Features | Stigmator Alignment)

- Eucentric Height: What it means, When to use it & How to get there

- Adjusting TLD Voltage to Capture SE vs. BSE Signal

Graphical Handouts

Presentations

- Scanning Electron Microscopy: Principles, Techniques & Applications (includes sides on EDS & WDS)

Manufacturer Manuals

- Nova NanoLab Operation Manual

- Gas Injection Systems – Deposition of Tungsten (Technical Note)

- Gas Injection Systems – Delineation Etch for SiO2 (Technical Note)

- Gas Injection Systems – Selective Carbon Etching (Technical Note)

- Gas Injection Systems – Beam Chemistries Presentation

- Scripting – AutoScript Language Manual (year 2000 Technical Note: most complete)

- Scripting – AutoScript Language Manual (year 2005 Technical Note: less complete, still useful)

- Scripting – RunScript Manual

Simulation Software

- CASINO Electron Beam Simulation Software – simulate e-beam/specimen interactions (very useful for EDS & WDS)

- The Stopping & Range of Ions in Matter (SRIM) – simulate i-beam/specimen interactions

Calibrate Measurements with NIST Standard

- The KNI has a NIST-traceable standard against which SEM measurements can be compared. See Slides 54-55 of the SEM Presentation for details. Ask staff for help finding and using the standard in the lab.

Sample Preparation

- Use the Carbon Evaporator to make non-conductive samples conductive by applying 2-10 nm of evaporated carbon.

- Use the O2/Ar Plasma Cleaner to remove hydrocarbons from the sample surface to avoid creating dark contamination spots on your features while imaging them.

Order Your Own Stubs

- Stubs used for mounting specimens are considered a personal, consumable item in the KNI. There are some old stubs at each SEM, yet you should buy your own so that you can keep them clean and available to you. There are many stub geometries and configurations, some of which will be right for you to purchase and keep with your other cleanroom items.

- Buy stubs with copper clips (recommended for most devices, especially those with non-conductive substrates)

- Buy stubs without copper clips (OK for devices with conductive substrates)

Specifications

Manufacturer Specifications

- Nova 200 NanoLab Data Sheet (not all parameters apply to our instrument, see below for details specific to the KNI's Nova 200)

SEM Specifications

- Minimum Feature Size Resolved in Immersion Mode: ~5 nm

- Voltage Range: 0.2 to 30.0 kV

- Current Range: ~10 pA to 20 nA

- Apertures: 30 μm, 40 μm, 50 μm, 100 μm

- Eucentric Height: ~4.8 mm working distance (WD)

- Stage Range: +/- 25 mm X & Y travel, 50 mm Z travel, -12 to 58° tilt, 360° rotation

- ETD Grid Bias Range: -150 to 300 V

- TLD Bias Range: -100 to 150 V

- Ultimate Vacuum: 5e-6 mbar